Description

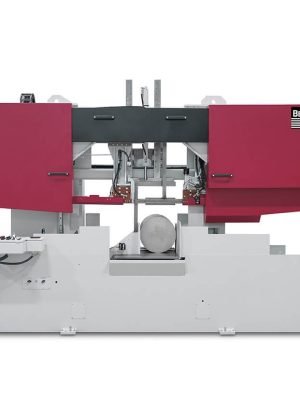

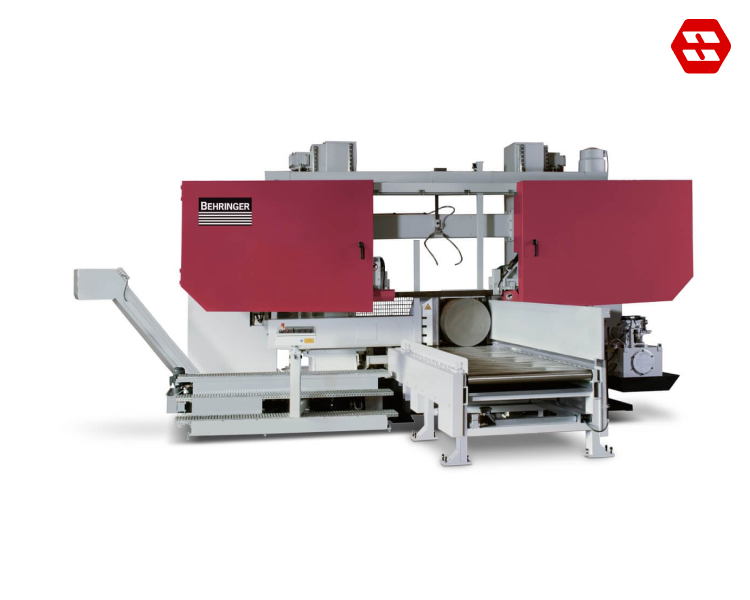

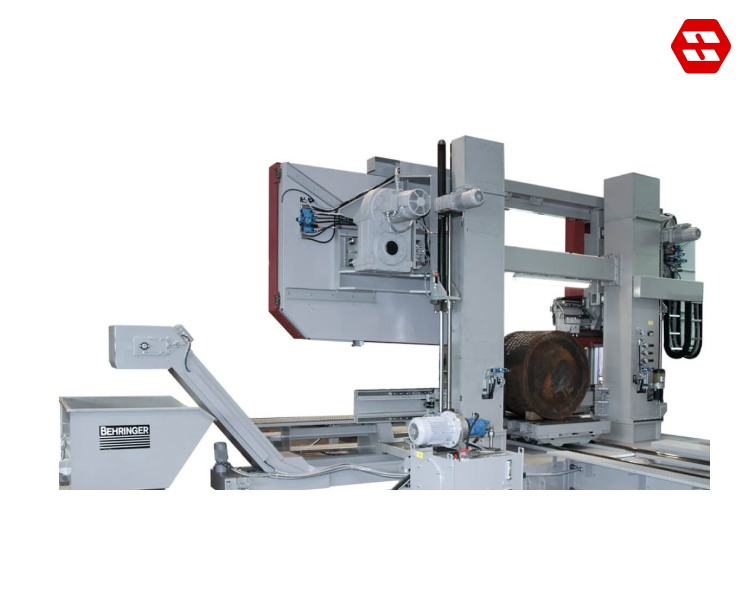

Large Bandsaw HBP1500

An efficient choice for steel finishing and the steel trade, BEHRINGER's large horizontal bandsaws with roller conveyor stand out as versatile workhorses. Particularly adept at cutting lengthy solid materials—be it rolled or rough turned—or processing large pipes, these saws significantly boost productivity.

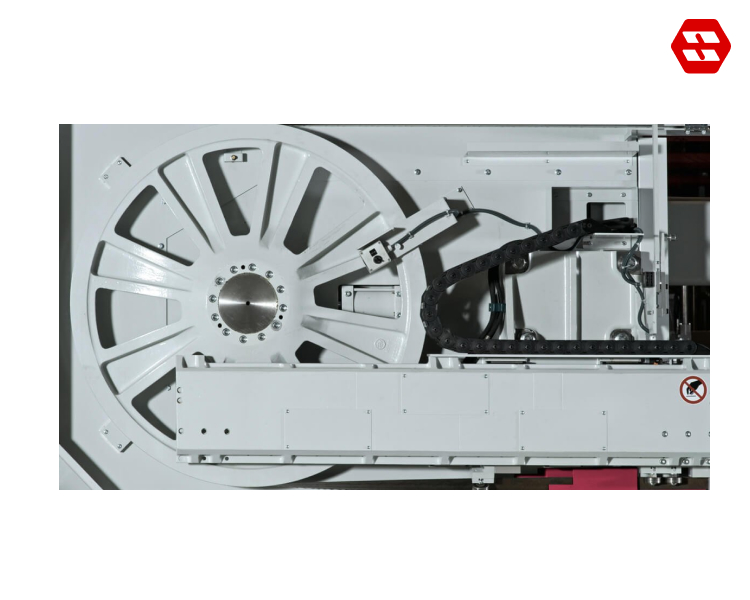

Servo Feed System

The BEHRINGER servo feed system with cutting pressure control produces constant chip removal, especially with slow feed movements. Large and difficult-to-cut materials are thus sawn with the highest cutting performance and at the same time longer blade life.

Cast Iron Band Guiding Parts

Cast iron band guiding parts provide essential support and stability to bandsaw blades during cutting operations. Renowned for their durability and heat resistance, these components ensure precise and consistent cuts in metalworking applications.

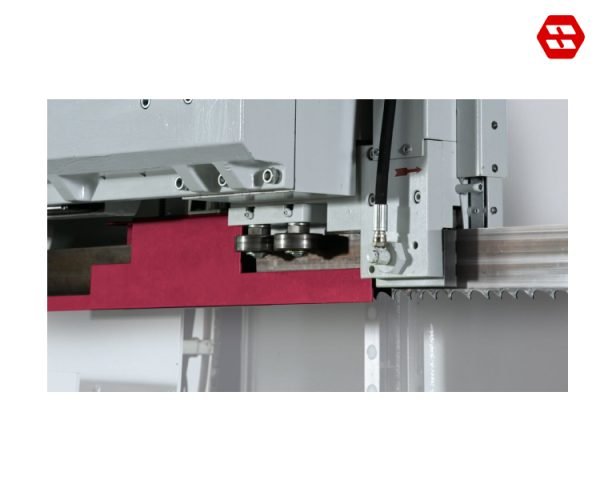

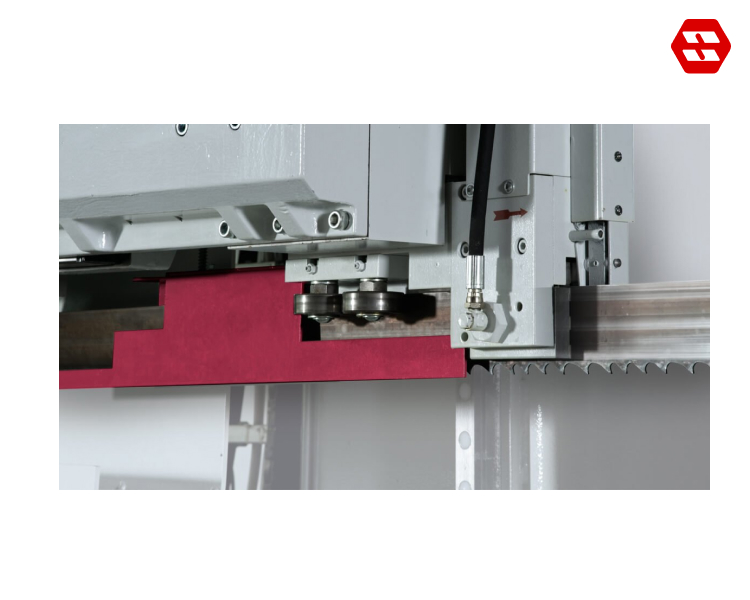

Carbide Blade Guides

Carbide blade guides represent the pinnacle of precision and durability in bandsaw blade guidance. Crafted from high-quality carbide materials, these guides offer exceptional wear resistance and thermal stability, ensuring prolonged performance even in demanding cutting environments.

Process-Reliable Chip Disposal by Chain Conveyor

Achieve process-reliable chip disposal with a chain conveyor system. Designed for seamless removal of metal chips generated during machining processes, this solution ensures uninterrupted production by efficiently transporting chips away from the work area.

Optimum Accessibility

BEHRINGER attaches great importance to the aspect of maintenance and servicing: All the important parts and components are very accessible. The open design offers direct access to all wearing parts, optimizing both maintenance and repairs and simplifying saw blade changes.

Duplex Chip Brushes

Duplex chip brushes are essential tools for efficient chip removal in machining operations. Featuring dual brush heads, these tools effectively sweep away debris and chips from workpieces and machinery, ensuring cleanliness and preventing damage.

Features of The Large Bandsaw HBP1500

Blade Guiding Parts in Grey Cast Iron.

By dampening vibrations directly at the sawing point, blade-guiding elements made by BEHRINGER help to increase tool service life.

Powered Duplex Chip Brushes.

Actively clean the blade and prevent chips being drawn into the cutting channel.

Precise Guiding System in Portal Design.

The portal design of the machine concept is the most recognizable feature of the BEHRINGER large band saws.

Strong Saw Drive.

BEHRINGER large band saws feature a high-torque frequency controlled saw drive with heavyduty hollow shaft gearbox.

Efficient Chip Removal.

The chip conveyor is located directly underneath the sawing point, which catches the saw chips and surplus cooling emulsion.

Technical Data Large Bandsaw HBP1500

| Cutting Range | |

| Cutting range 90° round | 1,500 mm |

| Cutting range 90° flat | 1,500 x 1,500 mm |

| Smallest dimension to be sawn round | 400 mm |

| Smallest dimension to be sawn flat | 400 x 200 mm |

| Performance Characteristics | |

| Drive power | 15 kW |

| Blade speed | 8 – 84 m/min |

| Saw blade dimensions | 14,830 x 80 x 1.6 mm |

| Total power | 30 kW |

| Dimensions and Weight | |

| Length | 3,100 mm |

| Width | 7,800 mm |

| Height | 4,500 mm |

| Weight | 15,000 kg |

| Material support height | 700 mm |