Description

Tube Cutting Saw BTS 460 NC

Whether for industrial manufacturing or fabrication tasks, the BTS 460 NC enhances productivity and versatility, making it the ultimate choice for demanding tube cutting applications.With its robust construction and innovative features, including automatic material feeding and clamping, it ensures seamless operation and superior cutting quality.

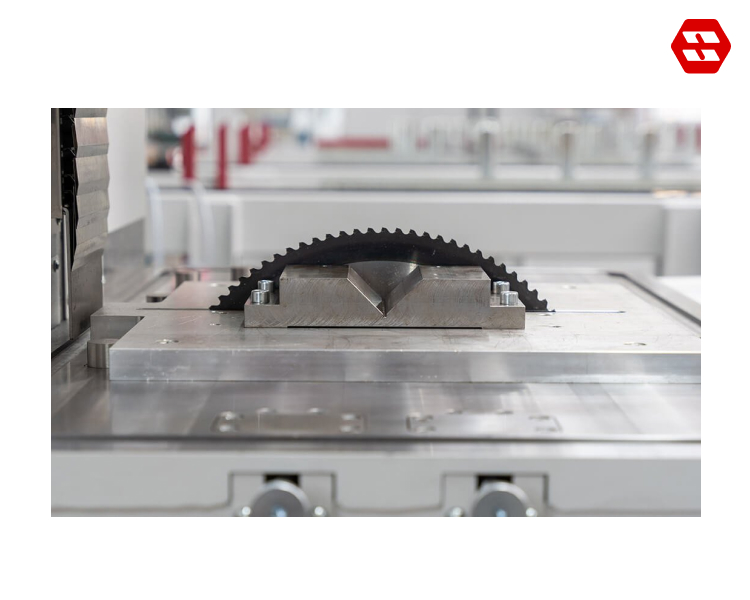

Individual Clamping Concepts via Standardised Mounts

Achieve tailored precision with our Circular Saw Machine Tube Cutting Saw PSU 450 GS by BEHRINGER, boasting individual clamping concepts via standardized mounts. This innovative feature ensures seamless and secure clamping of diverse tube shapes and sizes, optimizing cutting accuracy and efficiency.

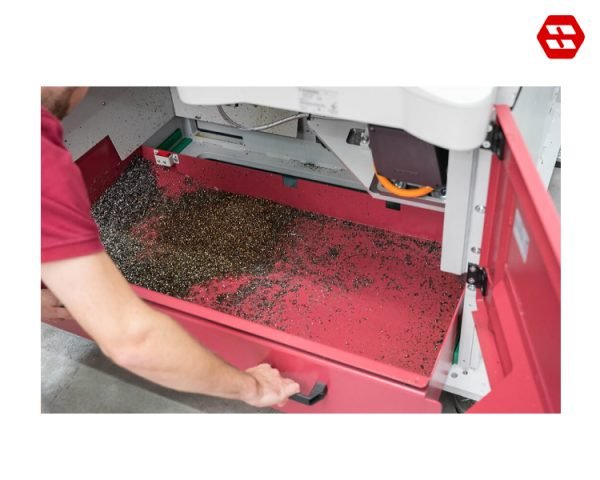

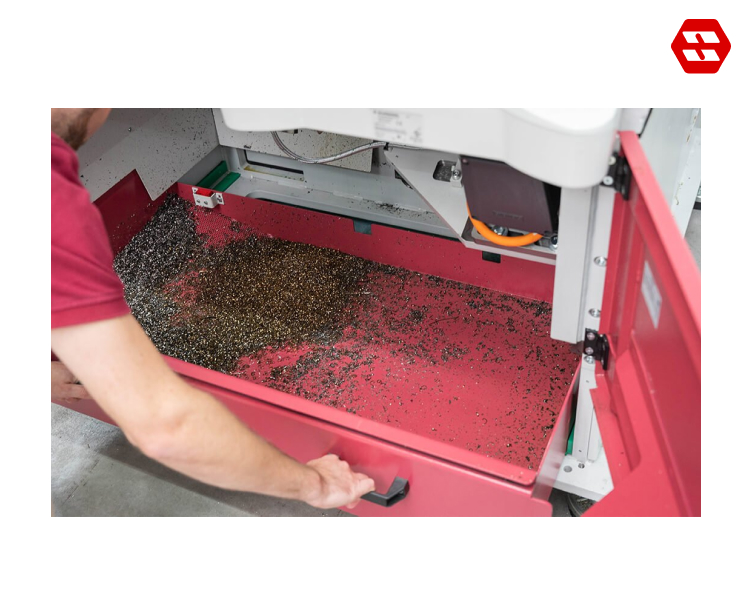

Chip Drawer

Efficiently manage metal shavings and debris with our Chip Drawer, an essential component of our cutting-edge machinery. Designed for easy installation and maintenance, the Chip Drawer seamlessly collects and stores chips generated during cutting processes, keeping workspaces clean and organized.

Control Surface

Experience unparalleled control and precision with our cutting-edge Control Surface. Designed for intuitive operation and seamless integration with our machinery, this surface provides a user-friendly interface for adjusting parameters, monitoring performance, and managing cutting processes with ease.

RFID Unit

Maximize efficiency and traceability in your metalworking operations with our RFID unit. This advanced technology seamlessly integrates with our machinery, allowing for automated identification and tracking of workpieces throughout the production process.

Individual Devices for Clamping

Optimize precision and versatility in your metalworking tasks with our Individual Clamping Devices. Engineered for seamless integration with our machinery, these devices offer tailored solutions for securing workpieces of various shapes and sizes.

Features of The Tube Cutting Saw BTS 460 NC

Micro Spray System.

When sawing profiles, pipes and solid material, the standard minimum quantity lubrication system delivers the best results. The saw blade is constantly moistened with cutting oil via a nozzle.

Stable,Low-vibration Gearbox.

The heart of the saw unit is the backlash-free pretensioned worm gear drive from our own production.

Optimum Chip Flow.

Also when sawing tubes and hollow profiles due to the saw feed from bottom up.

Sturdy Machine Base.

The heavy machine stand and the vibration-damping cast iron components made by BEHRINGER ensure a low-vibration sawing process and thus an increase in tool life.

Adjustable Saw Entry and Exit Point.

The entry and exit point of the tube cutting saw to the material can be freely adjusted for the use of various fixtures.

HSS and Carbide Saw Blades.

The saw is suitable for the economical use of carbide and HSS saw blades.

Simple, Intuitive Control.

Everything under control. The control system is self-explanatory, simple, avoids operating errors and allows quick navigation in the various programmes.

Servo-driven Workpiece Clamping.

Guarantees process-reliable and repeatable clamping of materials of any shape and wall thickness.

Optimum Chip Flow.

Also when sawing tubes and hollow profiles due to the saw feed from bottom up.

Technical Data Tube Cutting Saw BTS 460 NC

| Cutting Range | |

| Cutting range round | 165 mm |

| Smallest dimension to be sawn round | 10 mm |

| Performance Characteristics | |

| Drive power | 11 kW |

| RPM | 10 – 280 min-1 |

| Saw blade diameter | 350 – 460 mm |

| Saw feed | servo driven |

| Material clamping | servo driven |

| Dimensions and Weight | |

| Length | 1,465 mm |

| Width | 1,400 mm |

| Height | 2,230 mm |

| Weight | 2,500 kg |

| Material support height | 1,000 mm |