Description

3D Saw HBE320-523 3D

Presenting the adaptable cutting solution for additively manufactured components, the HBE320-523 3D Horizontal Bandsaw is engineered to cut 3D printing plates of various sizes up to 520 x 300 mm. Customizable work holding facilitates flexible cutting of plates in different sizes and shapes, enhancing versatility.

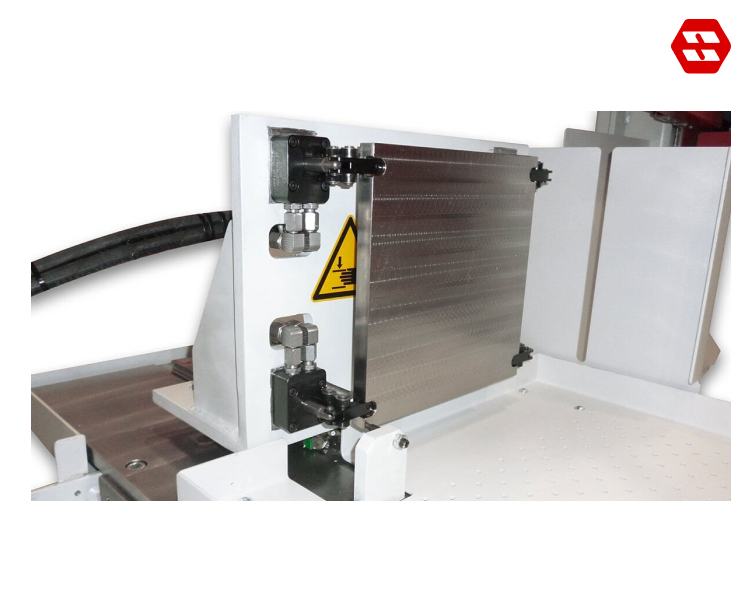

Easy Setup Due to Zero Point Stop System

Effortlessly set up your cutting operations with the zero-point stop system, ensuring precise alignment and streamlined processes.

Coolant Filtration

A standard filter unit cleans the coolant from particles and powder residues that are released during the sawing of printed components. This unit noticeably increases the service life of the coolant.

Sawing Process Significantly Faster Than Wire EDM Machines

Experience dramatically accelerated cutting processes with speeds surpassing those of wire EDM machines.

Individual Clamping Concepts (E.G. Hydraulic Clamping units)

Tailor your clamping solutions to your exact needs with customizable options such as hydraulic clamping units, ensuring optimal precision and efficiency.

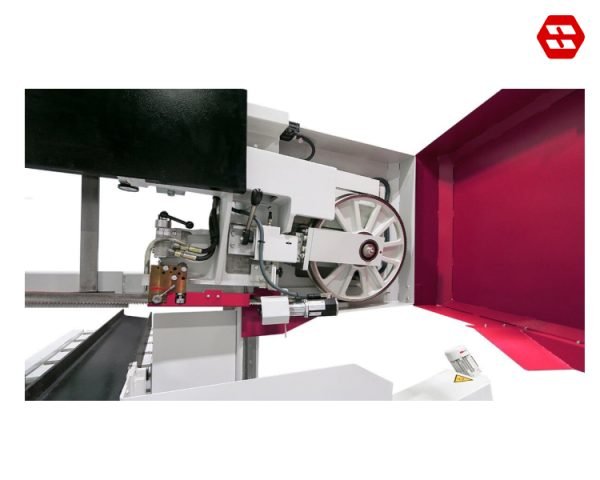

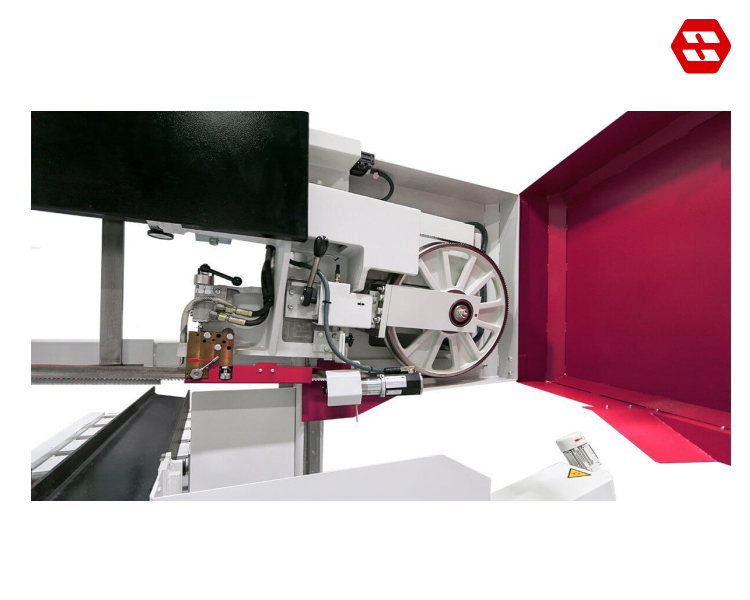

Cast Iron Band Guiding Parts

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

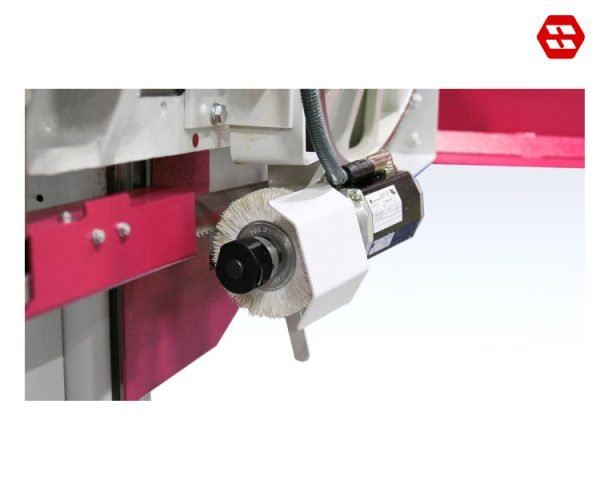

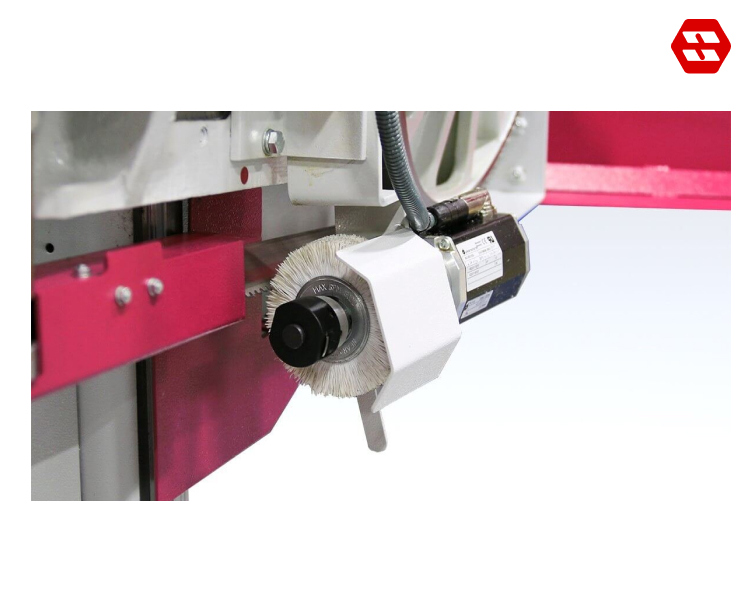

Electrically Driven Chip Brush

With BEHRINGER quick-change device for tool-free brush changes. The teeth of the saw band are protected by the special engagement angle.

Features of The 3D Saw HBE320-523 3D

Quick and Easy Loading and Unloading.

The shortest possible setup times are achieved because the HBE320-523 3D is equipped with a device for holding additively printed base plates.

Precision Portal-Design Guide System.

The combination of stable, low-vibration saw frame and the linear guide system in portal design ensure the best band sawing results and maximum service life.

Energy Efficient.

The use of modern drives and a special hydraulic system reduces energy consumption by approx. 30% compared to the previous model.

Clamping Options According to Customer Requirements.

The workpiece holder is equipped with a customised borehole pattern as standard to attach the 3D printing plates.

Zero-Point Stop System.

A clever solution for aligning the printed panels under the saw line is the standard zero-point stop system.

Sensitive BEHRINGER Cutting Pressure Control.

Increases the cutting performance when sawing 3D printed components, as it automatically adapts the saw feed of the machine to the changing material cross-sections.

Coolant Cleaning.

A standard filter unit cleans the coolant from particles and powder residues that are released during the sawing of printed components.

Technical Data 3D Saw HBE320-523 3D

| Cutting Range | |

| Maximum printing plate size flat W x H | 520 x 300 mm |

| Minimum printing plate size flat W x H | 100 x 100 mm |

| Maximum print height | 400 mm |

| Minimum plate thickness | 20 mm |

| Performance Characteristics | |

| Drive power | 2.6 kW |

| Blade speed | 15-110 m/min |

| Saw blade dimensions | 5,300 x 34 x 1.1 mm |

| Total power | 3.7 kW |

| Printing plate positioning | mechanical zero-point stop |

| Dimensions and Weight | |

| Length | 1,150 mm |

| Width | 2,750 mm |

| Height | 2,150 mm |

| Weight | 1,600 kg |

| Material support height | 830 mm |