Description

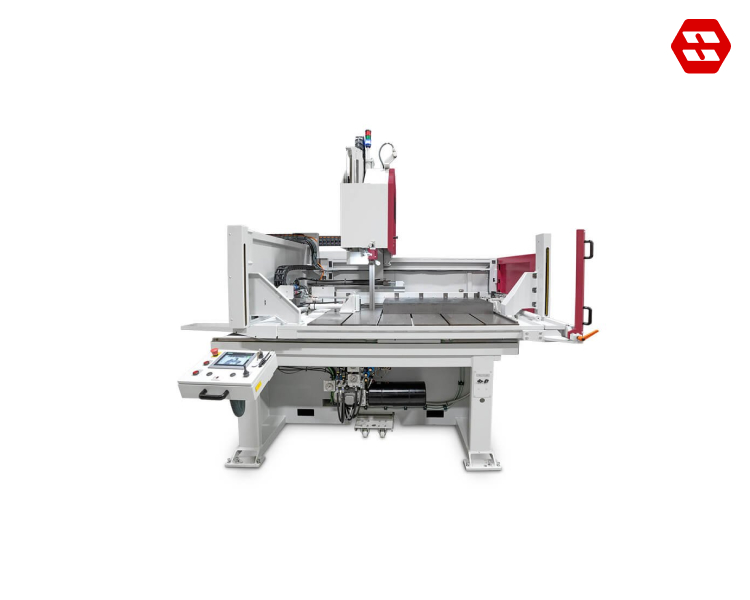

Automatic Table LPS-TA

The Automatic Table Bandsaw LPS-TA is the ideal solution from BEHRINGER when it comes to fully automatic cutting of small plates and blocks. By producing flat and rectangular material from sheets, advantages can be achieved in material purchasing and significantly reduced storage costs.

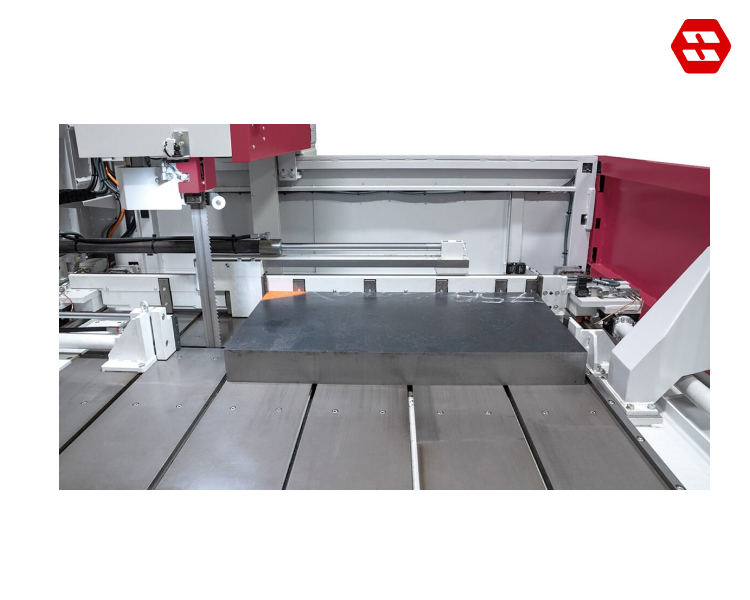

Automatic Material Positioning

Experience seamless precision with our automatic material positioning system. Engineered for efficiency and accuracy, this advanced technology ensures effortless and precise alignment of materials for cutting.

Compact Dimensions Due to Intelligent Protection Devices

Maximize space efficiency with our compact bandsaw machine, engineered with intelligent protection devices. Designed to prioritize safety without compromising on functionality, this innovative feature ensures optimal performance while minimizing footprint.

Intuitive Touch Control System

Experience seamless control with our intuitive touch control system. Engineered for effortless operation, this advanced technology offers intuitive navigation and precise adjustments.

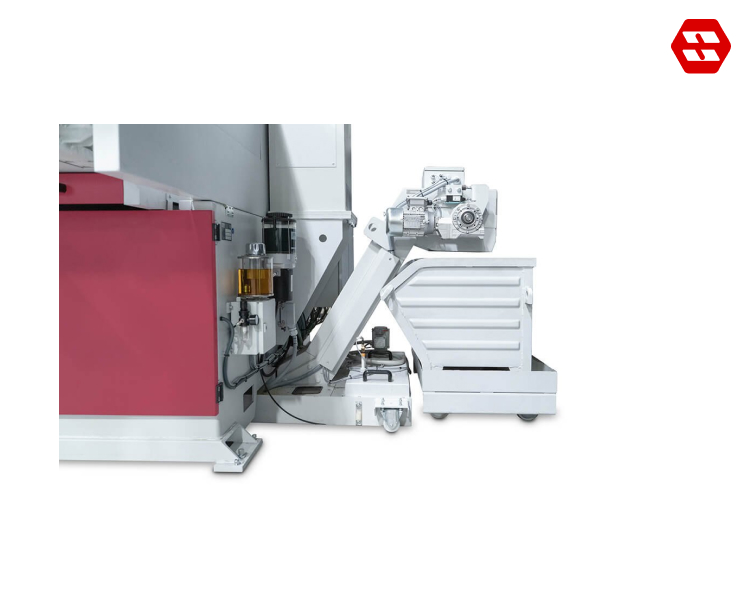

Chip Conveyor With Integrated Coolant Tank

A generously sized chip conveyor with integrated coolant tank is located under the saw unit, directly in the chip flow direction. Any chips and coolant are collected here and separated.

Features of The Table Bandsaw LPS-TA

Unsurpassed Precision and Cutting Performance.

The high cutting accuracy, quiet running and long blade life are all down to the special torsion resistant design of the saw frame.

Advantages in Material Purchasing.

By producing flat materials from large sheets, rationalisation effects can be achieved both in warehousing and in the purchase of raw materials.

Powered Duplex Chip Brushes.

Actively clean the blade and prevent chips being drawn into the cutting channel.

Movable Material Support Table.

For easy loading and unloading by crane, the material table of the vertical saw can be moved out from under the saw unit.

Automatic Feeding Unit.

Thanks to the combination of NC-controlled feeding unit and intelligent control, plates can be separated into strips fully automatically.

Quick Bandsaw Blade Change.

Quick and easy – tool-free bandsaw blade changes mean shortest set-up times. Just a few simple steps are all that is needed to change the bandsaw blade of the block saw.

Cast Iron Band Guiding Parts.

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

Technical Data Table Bandsaw LPS-TA

| Cutting Range | |

| Cutting length | 1,520 mm |

| Cutting width | 620 mm |

| Cutting height | 400 mm |

| Minimum cutting width | 10 mm |

| Minimum cutting height | 15 mm |

| Performance Characteristics | |

| Drive power | 4 kW |

| Blade speed | 17 – 120 m/min |

| Saw blade dimensions | 5,730 x 41 x 1.3 mm |

| Total power | 6 kW |

| Material feeding length | 600 mm |

| Supporting area inside table | 1,540 x 620 mm |

| Supporting area outside table | 1,540 x 640 mm |

| Maximum table load | 3,000 kg |

| Dimensions and Weight | |

| Length | 4,250 mm |

| Width | 3,450 mm |

| Height | 3,200 mm |

| Weight | 4,000 kg |

| Material support height | 1,200mm |