Description

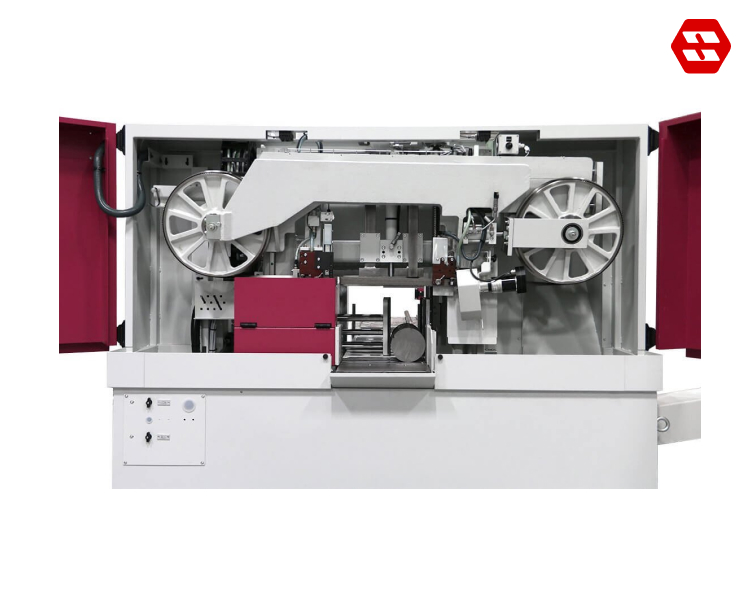

HBE321A Dynamic

The BEHRINGER HBE321A Dynamic automatic bandsaw is crafted for efficient operation in both industrial settings and the steel industry. It provides high-quality cuts with minimal deviation across a broad spectrum of materials, from simple to complex metals and plastics.

Servo-Downfeed With Cutting Pressure Control

The stable cast iron saw frame is designed to offer unparalleled durability and rigidity for precision cutting. Its robust construction minimizes vibrations during operation, ensuring smooth, accurate cuts and extended machine life.

Intuitive BehrCtrl10 Touch Control

Experience intuitive control: BehrCtrl10 touchscreen

Stable Cast Iron Saw Frame

The stable cast iron saw frame is designed to offer unparalleled durability and rigidity for precision cutting. Its robust construction minimizes vibrations during operation, ensuring smooth, accurate cuts and extended machine life.

Electrically Driven Chip Brush

With BEHRINGER quick-change device for tool-free brush changes. The teeth of the saw band are protected by the special engagement angle.

Features of The Production Bandsaw HBE321A Performance

Precision Portal-Design Guide System.

The combination of stable, low-vibration saw frame and the linear guide system in portal design ensure the best band sawing results and maximum service life.

Energy Efficient.

The use of modern drives and a special hydraulic system reduces energy consumption by approx. 30% compared to the previous model.

Cast Iron Band Guiding Parts.

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

Servo Downfeed System.

The saw feed is carried out by means of a ball screw and servo motor. This results in significantly shorter idle times and more precise saw feeds.

Auto-Feed-Control.

Selection of the material in an extensive material database. The AFC automatically calculates the optimal values for saw feed and cutting speed.

Automatic guide arm.

Optimum sawing result without any adjustments - even with frequently changing material sizes.

Sensitive BEHRINGER Cutting Pressure control.

Increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections.

Double Clamping Vice.

Offers process reliability - especially when sawing bundles or making single cuts. The clamping jaws of the band saw are arranged on the infeed

Easy to Use.

Quick and easy operation of all functions of the automatic band saw via touch control.

Technical Data Horizontal Bandsaw HBE321A Dynamic

| Cutting Range | |

| Cutting range 90° round | 320 mm |

| Cutting range 90° flat | 350 x 320 mm |

| Smallest dimension to be sawn round | 10 mm |

| Smallest dimension to be sawn flat | 10 x 8 mm |

| Performance Characteristics | |

| Feeding length single stroke | 650 mm |

| Drive power | 2.6 kW |

| Blade speed | 15 – 110 m/min |

| Saw blade dimensions | 4,440 x 34 x 1.1 mm |

| Rest piece length in automatic operation | 70 mm |

| Total power | 3.7 kW |

| Saw feed | servo-feed via ball screw |

| Material feed | ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimensions Characteristics | |

| Length | 1,850 mm |

| Width | 2,300 mm |

| Height | 1,820 mm |

| Weight | 1,900 kg |

| Material support height | 800 mm |