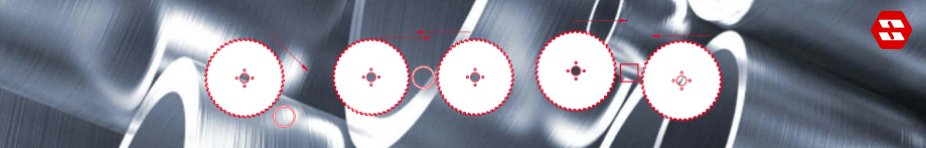

Description

Single and Twin Cut-Off Without Inside Scarf

The ScarfMaster, featuring PVD-coated carbide tips, is specifically engineered for flying cut-off tasks that involve significant inside scarf removal. Its unique tooth design, paired with exceptionally shock-resistant carbide tips, ensures optimal performance. The saw body's robust shoulders bolster the teeth, providing unparalleled stability and resistance to breakage.

Application

Single and twin flying cut-off machines designed for TCT cutting with small or no ID-scarf

Advantages

High line speed.

Increased uptime.

High blade life.

Cuts heavy ID scarf.

Cuts high tensile API Pipes (up to 1.800 N/mm2).

Various tooth geometries available.

Applications

Flying cut-off applications dealing with heavy ID Scarf.

Cutting speed: 400 – 500 m/min (choose max available).

Tooth load 1/2/3: relation 1/1/1. Starting value 0.04 mm/tooth.

ScarfMaster saw blades are available for flying cut-off machines, such as MTM, OTO mills, Nakata and Olimpia.