Description

High Speed Circular Saw HCS 150 E

Whether for fabrication or manufacturing, the HCS 150 E sets the standard for high-performance metal cutting. Elevate your productivity and precision with the cutting-edge capabilities of the HCS 150 E Circular Saw Machine.

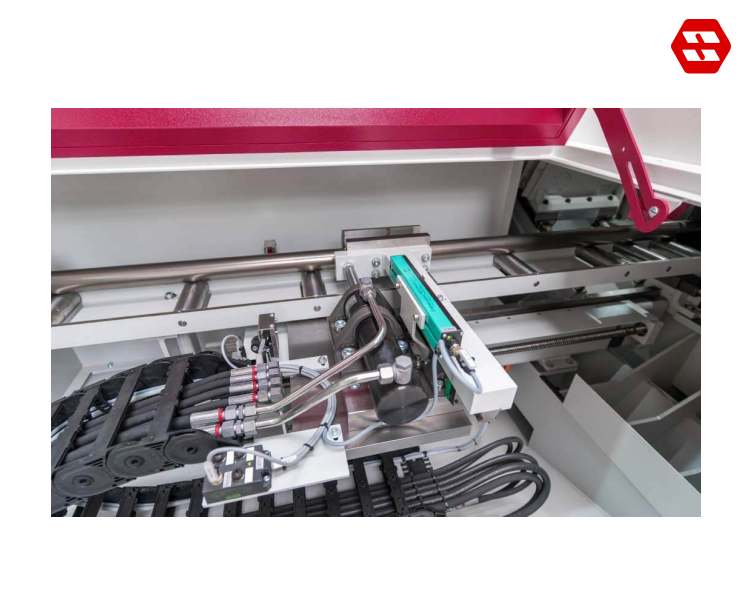

HCS Saw Blade Guide

The HCS Saw Blade Guide is a pivotal component designed to enhance precision and stability in cutting operations. Crafted with meticulous attention to detail, this guide ensures the saw blade operates with optimal alignment, significantly reducing vibrations and enhancing cut quality.

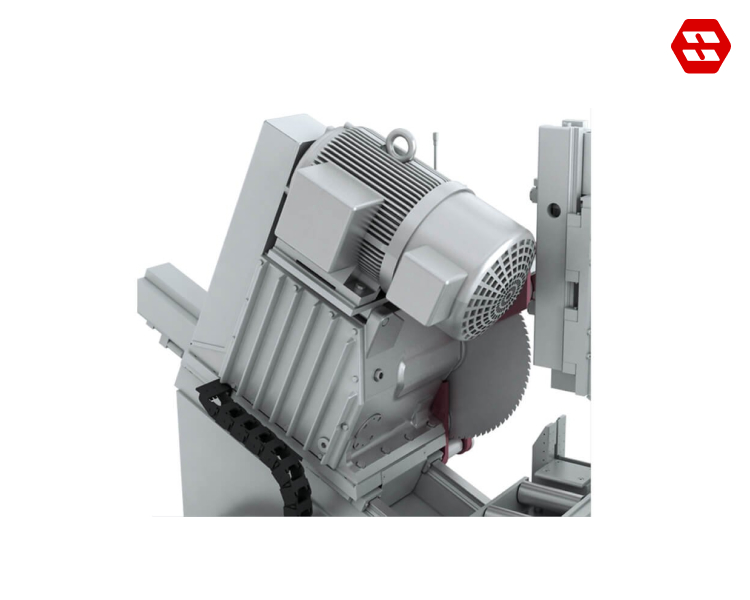

Stable,Low-Vibration Gearbox

Our machinery is equipped with a Stable, Low-Vibration Gearbox, designed to enhance both performance and precision in demanding industrial environments. This advanced gearbox minimizes vibrations significantly, ensuring smoother operations and higher quality cuts with reduced noise levels.

3-Point Material Clamping

The 3-Point Material Clamping system offers superior stability and precision for cutting operations. Designed to securely hold materials in place from three different points, this system ensures a firm grip, minimizing movement and vibration during cutting.

Powerful Control of The Industrial Circular Saw

Experience unmatched precision and efficiency with the Powerful Control system of our Industrial Circular Saw. Engineered to deliver comprehensive command over cutting operations, this advanced control system allows for intricate adjustments and real-time monitoring, ensuring optimal performance.

Servo-Driven Feeding Gripper

Swiftly positions the material precisely and in a matter of seconds. Its advantages are: accurate cutting length and short cycle times with tight tolerances.

Chip Conveyor

The Chip Conveyor is an essential accessory for maintaining cleanliness and efficiency in metalworking environments. Designed to automatically remove and transport chips and debris away from the cutting area, it ensures a cleaner workspace and reduces downtime associated with manual cleaning.

Sorting Switch

The Sorting Switch is a pivotal component in automated cutting systems, designed to enhance operational efficiency and accuracy. This innovative feature intelligently directs finished parts to designated locations, streamlining the sorting process and minimizing manual intervention.

Spray Mist Extraction

The Spray Mist Extraction system is an advanced solution designed to improve air quality and safety in metalworking environments. This system efficiently removes airborne mist and particulates generated during cutting processes, ensuring a cleaner, healthier workspace.

Remote Maintenance as Standard

Benefit from seamless equipment upkeep with Remote Maintenance as standard. This feature enables technicians to diagnose and troubleshoot machinery from afar, minimizing downtime and maximizing efficiency.

Features of The High Speed Circular Saw HCS 150 E

Robust,Low-Vibration Gear Unit.

The heart of the saw unit is the worm gear unit, by BEHRINGER EISELE. It heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface and the blade life.

Cooling Systems.

The industrial circular saws of the HCS-E series are equipped with a micro-spray unit as standard. This ensures precise cooling and minimal lubrication of the tool.

Extremely Solid Construction.

The extremely stable and solid machine bed is the basis of every HCS high speed circular saw. It ensures excellent vibration damping and ideal power flow.

Linear Guided Saw Feed.

The saw unit is moved dynamically through the entire cutting area via two linear guides in conjunction with a ball screw and a servo motor.

Simple and Intuitive Operation of The Control Unit.

Everything under control! The control unit is self explanatory and easy to operate; operating mistakes are avoided and it allows for quick navigation within the program menu.

Short Cycle Times.

by electronic cutting height adjustment and rapid return of the saw blade.

Technical Data High Speed Circular Saw

HCS 150 E

| Cutting Range | |

| Cutting range 90° round | 152,4 mm |

| Cutting range 90° square | 130x 130 mm |

| Smallest dimension to be sawn round | 10 mm |

| Smallest dimension to be sawn square | 10 x 10 mm |

| Performance Characteristics | |

| Drive power | 15 kW |

| RPM | 20 – 250 min-1 |

| Saw blade diameter | 360 / 420 / 460 mm |

| Feeding length single stroke | 1,000 mm |

| Feed rate | 1,250 mm/s |

| Saw feed | servo-driven |

| Material clamping | hydraulic |

| Saw drive | frequency-controlled |

| Dimensions and Weight | |

| Length | 2,550 mm |

| Width | 1,900 mm |

| Height | 2,000 mm |

| Weight | 3,200 kg |

| Material support height | 1,170 mm |