Description

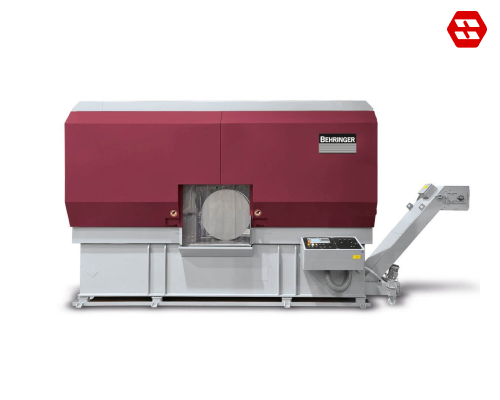

HBM800A Performance Automatic

The cutting-edge SpeedCutting technology integrated into the HBM800A high-speed saw series revolutionizes cutting performance, previously deemed unattainable. Particularly noteworthy is the HBM800A's prowess when cutting tool steels, stainless steels, or high-alloy materials like Inconel or Titanium.

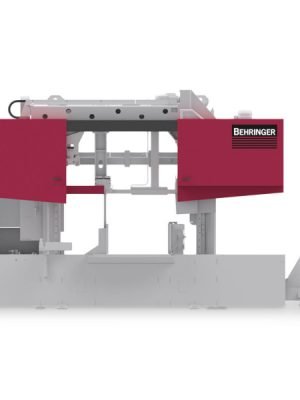

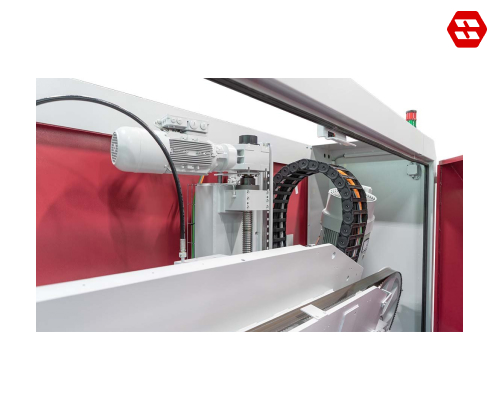

High-Performance Sawing Unit With BEHRINGER Speed-Cutting Technology

The high-performance sawing unit, featuring BEHRINGER Speed-Cutting technology, delivers unprecedented precision and efficiency in cutting operations.

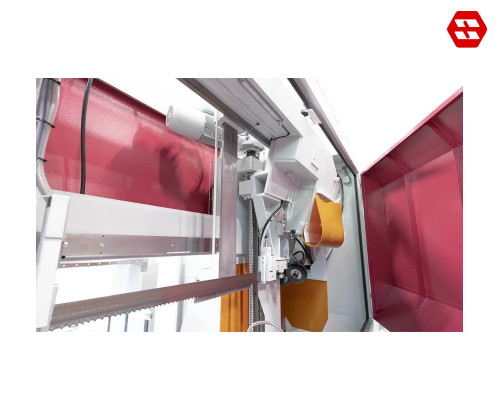

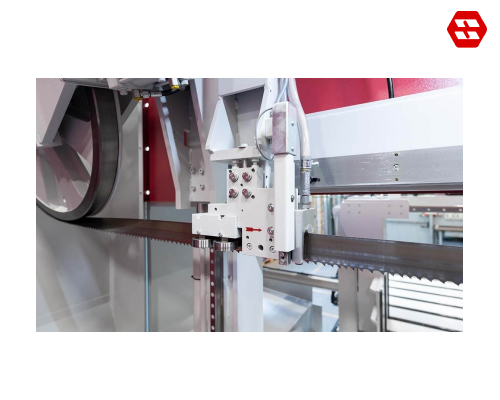

HBM Band Guide With High-Performance Cooling

The HBM band guide with high-performance cooling ensures optimal temperature control for precise and efficient bandsaw operations.

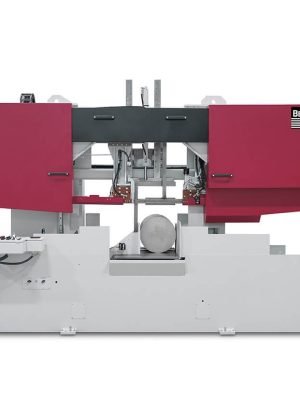

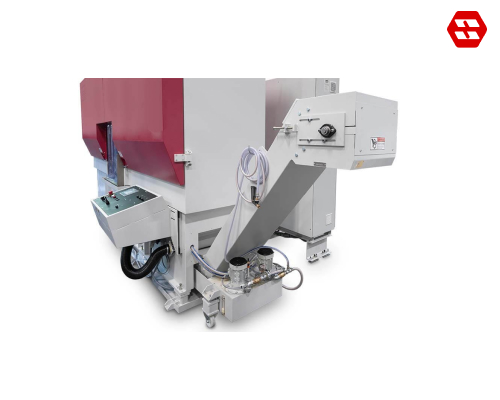

Chip Conveyor With Integrated Coolant Tank

The chip conveyor with integrated coolant tank efficiently manages chip removal while providing a continuous supply of coolant for optimal machining performance.

Features of The Production Bandsaw HBM800A

Optimum Chip Disposal.

Highest cutting performance requires high standards of chip disposal. The wide, funnel-shaped machine base allows chips to fly freely into the chip conveyor with integrated coolant tank below.

Precision Portal-Design Guide System.

The combination of stable, low-vibration saw frame and the linear guide system in portal design ensure the best band sawing results and maximum service life.

Sensitive BEHRINGER Cutting Pressure Control.

Increases the cutting performance when sawing tubes and profiles, as it automatically adapts the saw feed of the machine to the changing material cross-sections.

Prepared For Automation.

A powerful machine concept puts high demands on material handling. The production band saws of the HBM series are often configured as automated sawing systems.

Economical Use of Carbide Saw Blades.

Due to robust design, use of latest servo technology and well dimensioned chip disposal.

Servo Downfeed System.

The saw feed is carried out by means of a ball screw and servo motor. This results in significantly shorter idle times and more precise saw feeds.

Automatic Guide Arm.

Optimum sawing result without any adjustments - even with frequently changing material sizes.

Cast Iron Band Guiding Parts.

Are made by BEHRINGER and provide vibration damping directly at the cutting edge, thus increasing tool life.

Technical Data Production Bandsaw HBM800A

| Cutting Range | |

| Cutting range 90° round | 800 mm |

| Cutting range 90° flat | 800 x 800 mm |

| Smallest dimension to be sawn round | 50 mm |

| Smallest dimension to be sawn flat | 50 x 50 mm |

| Performance Characteristics | |

| Feeding length single stroke | 600 mm |

| Drive power | 11 kW |

| Blade speed | 17 – 120 m/min |

| Saw blade dimensions | 9,400 x 67 x 1.6 mm |

| Rest piece length in automatic operation | 70 mm |

| Total power | 19 kW |

| Saw feed | servo-feed via ball screw |

| Material feed | ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimensions and Weight | |

| Length | 2,900 mm |

| Width | 5,150 mm |

| Height | 3,000 mm |

| Weight | 7.800 kg |

| Material support height | 800 mm |